We ensure electrical equipment used are suitable and appropriately certified for the relevant area as required by laws, regulations and standards developed in most countries. Equipment used in wrong hazardous zones may potentially cause explosions that might harm people and damage property. Our surveyors are well-experienced and certified, having completed jobs in many parts of the world and placing customers’ minds at ease.

Megawatts has a team of CompEx certified and experienced inspectors. Ex Survey is a process where all electrical equipment installed in a potentially hazardous area are subjected to three grades of inspection – Visual, Close and Detailed. It will be carried out either as an initial, periodic or sample inspection.

All electrical equipment is inspected, detail recorded and tagged to form the assets, known as “Hazardous Area Equipment Register” (HAER).

Requirements for other documentation that may be necessary are provided in IEC 60079-14 and IEC 60079-19:

Megawatts provides a team of certified thermographers who are experienced in conducting thermography inspection surveys, putting customers’ minds at ease.

Thermography survey is a condition-monitoring preventative maintenance and process monitoring application that determines faults. Potential applications include:

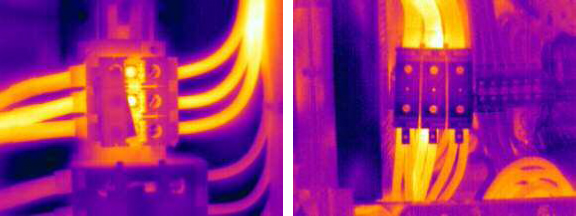

We focus on electrical applications thermography inspection where faults in electrical installation often appear as “hot-spots” that can be detected by the Thermal Imager. Hot spots are often the result of increased resistance in a circuit, overloading, or insulation failure.

This inspection method is based on the fact that most components in a system show an increase in temperature when malfunctioning. The increase in temperature in an electrical circuit could be due to loose connections or a worn bearing in the case of mechanical equipment. By observing the heat patterns in operational system components, faults can be located, and their gravity evaluated.

Frequent periodic thermography survey is best to be conducted under full operational conditions and hence. there should be no loss of production with advantages of:

The thermography inspection processing system provides a report writing facility. This may be used to provide a hardcopy record of the thermal image accompanied by an imported photograph and any other information for reference purposes such as hotspot analysis and recommendation.